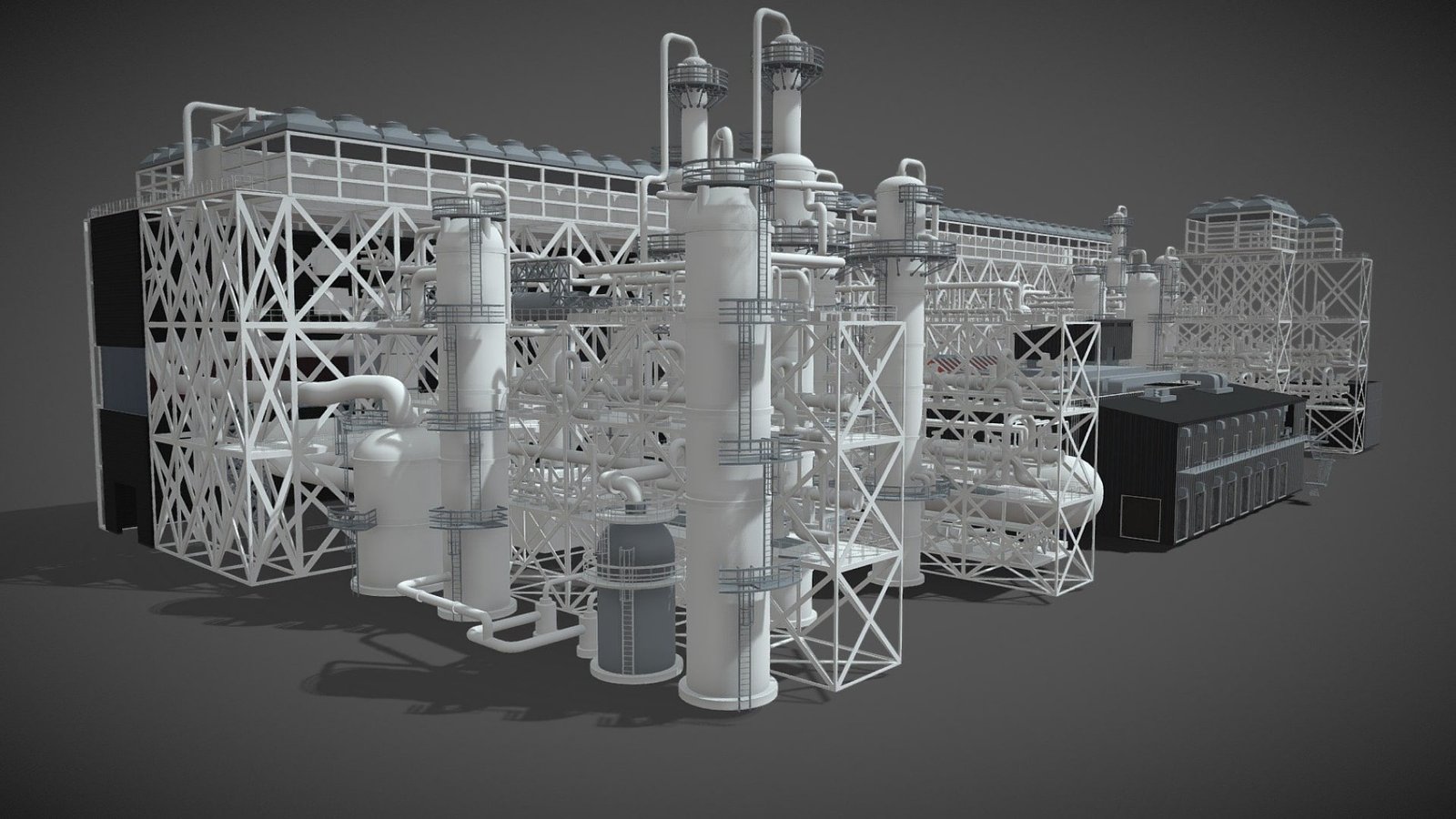

3D Modelling

3D Modelling

Our 3D Modelling activities

- Gather information based on Verification of Piping Systems as defined on Piping GA and P&IDs versus Actual systems and installation on the facility.

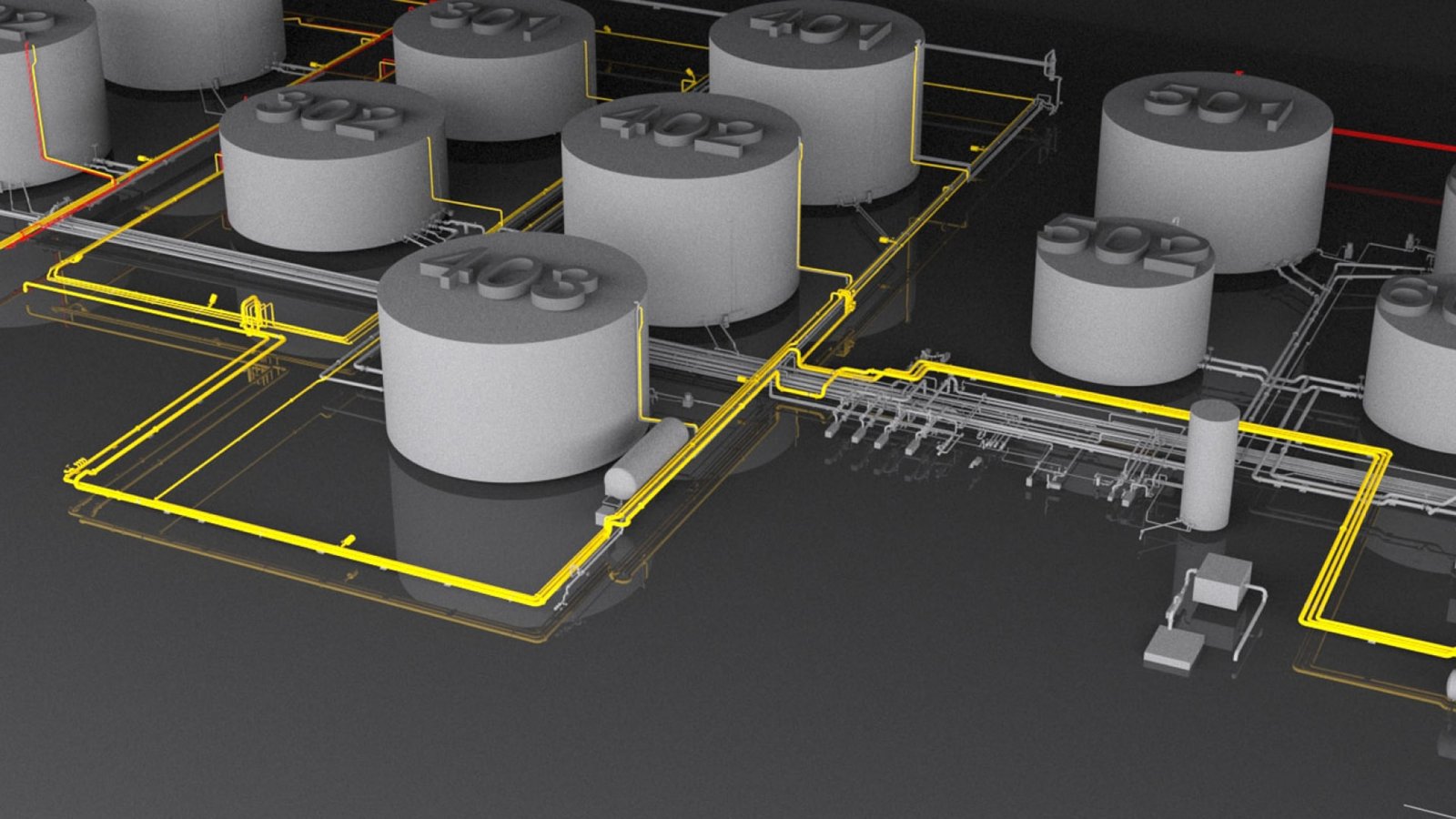

- Coordination in develop SP3D,PDMS 3D Model with existing facility & Update / modified facilities information for all Piping Systems as defined on P&IDs.

- Support Piping Design team in Piping Studies.

- Verification of Pipe routings & pipe supports at platform facilities.

- Main Participation to clarify queries raised during Model review at Design office.

- Site verification of Existing Facilities for Piping and identified highlighted constraint gaps.

- Meetings with Various Departments like Maintenance, Safety & Operational group personnel to review and resolve actual challenges in the field.

- Field deficiencies were observed to incorporate in the report.

- Preparation of Master deliverable Report, Iso Books.

- In Site Existing Gaps has been analyzed & comments have been provided for client review.

- Inter-disciplinary Co-ordination and Squad check.

Prepare Department Final Issue Package & hand over Client.

- Trained AVEVA PDMS for modules of Admin,Pargon,Specon,Draft, Piping, Equipment and Structural modeling, .

- Provide user support in running project using PDMS with generating reports.

- Able to create catalog for Piping material Specification,

- Customization and loading of piping material specification.

- Maintain project backup for 2D and 3D and able to restore the same as project archival and dump.